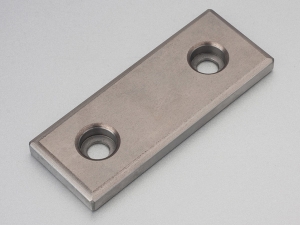

10mm Thick Wear Plate

1. The DNB-#200P10 10mm thick wear plate made by our company is based on a metallic material. Its surface is sintered with an alloy layer which contains a solid lubricant. The wear-resistant self-lubricating plate is subjected to oil-containing treatment.

2. Its solid lubricant is evenly dispersed in an alloy layer, so it can form a solid lubricant film with low shear strength when it starts sliding. It can be firmly attached to the bearing surface without cracking even under ultra high static load.

3. The 10mm thick wear plate not only protects shaft from abrasion, but also allows solid lubricating properties to be permanent. Both its hardness and wear resistance are twice as high as that of ordinary copper bushes.

4. As one of the machine parts, our product has been widely applied in the hydraulic metal processing equipment, tire moulds, hoisting machinery, and the mining machinery, etc. It can be used under conditions of high temperature, high load, low-speed heavy duty, and more.

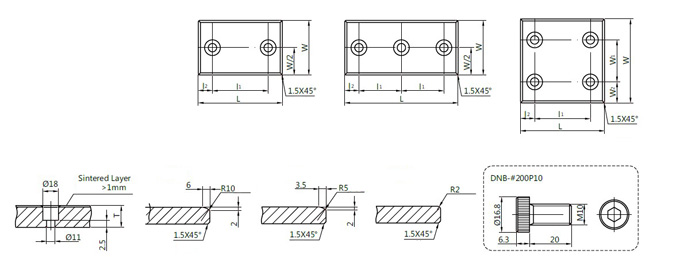

5. Please choose the part number on basis of thickness, width and length. For instance, the ordering code of the 10mm thick wear plate is DNB-#200P10-2875 under condition of 10mm thickness, 28mm width, and 75mm length.

Technical Parameters (Unit: mm)

| Parts No. | Width | Length | Thickness | Mounting holes Pitch | Number of Screw holes | Chamfered shape | ||||||||

| W | Tolerance | L | Tolerance | T | Tolerance | W1 | Tolerance | W2 | L1 | Tolerance | L2 | |||

| 28 | -0.1 -0.3 |

75 | -0.1 -0.3 |

10 | ±0.01 | - | - | - | 45 | ±0.2 | 15 | 2 | C | |

| 100 | - | - | - | 50 | 25 | |||||||||

| 125 | 75 | 25 | ||||||||||||

| 150 | - | - | - | 100 | 25 | |||||||||

| 38 | 75 | - | - | - | 45 | 15 | ||||||||

| 100 | - | - | - | 50 | 25 | |||||||||

| 125 | 75 | 25 | ||||||||||||

| 150 | - | - | - | 100 | 25 | |||||||||

| 48 | 75 | - | - | - | 45 | 15 | B | |||||||

| 100 | - | - | - | 50 | 25 | |||||||||

| 125 | - | - | - | 100 | 25 | |||||||||

| 150 | - | - | - | 100 | 25 | |||||||||

| 200 | - | - | - | 100 | 50 | |||||||||

| 250 | - | - | - | 45 | 25 | 3 | ||||||||

| 75 | 75 | - | - | - | 25 | 25 | 2 | A | ||||||

| 100 | - | - | - | 50 | 25 | |||||||||

| 125 | - | - | - | 75 | 25 | |||||||||

| 150 | - | - | - | 100 | 25 | |||||||||

| 200 | - | - | - | 150 | 25 | |||||||||

| 250 | - | - | - | 100 | 25 | 3 | ||||||||

| 300 | - | - | - | 100 | 50 | |||||||||

| 100 | 100 | 50 | ±0.2 | 25 | 50 | 25 | 4 | |||||||

| 125 | 75 | 25 | ||||||||||||

| 150 | 100 | 25 | ||||||||||||

| 200 | 150 | 25 | ||||||||||||

| 250 | 200 | 25 | ||||||||||||

| 300 | 200 | 50 | ||||||||||||

| 125 | 125 | 37.5 | 75 | 25 | ||||||||||

| 150 | 100 | 25 | ||||||||||||

| 200 | 150 | 25 | ||||||||||||

| 250 | 200 | 25 | ||||||||||||

| 300 | 200 | 50 | ||||||||||||

| 150 | 150 | 100 | 25 | 100 | 25 | |||||||||

| 200 | 150 | 25 | ||||||||||||

| 250 | 200 | 25 | ||||||||||||

Chinese

Chinese English

English